What are the common application scenarios of surfacing wear-resistant plates?

The core advantage of cladding wear-resistant plate is that the wear-resistant layer can be customized according to the working conditions (such as high hardness, impact resistance, corrosion resistance, and high temperature resistance). Therefore, it is widely used in key equipment components with high wear, high impact, and complex working conditions. Common scenarios are classified by industry as follows

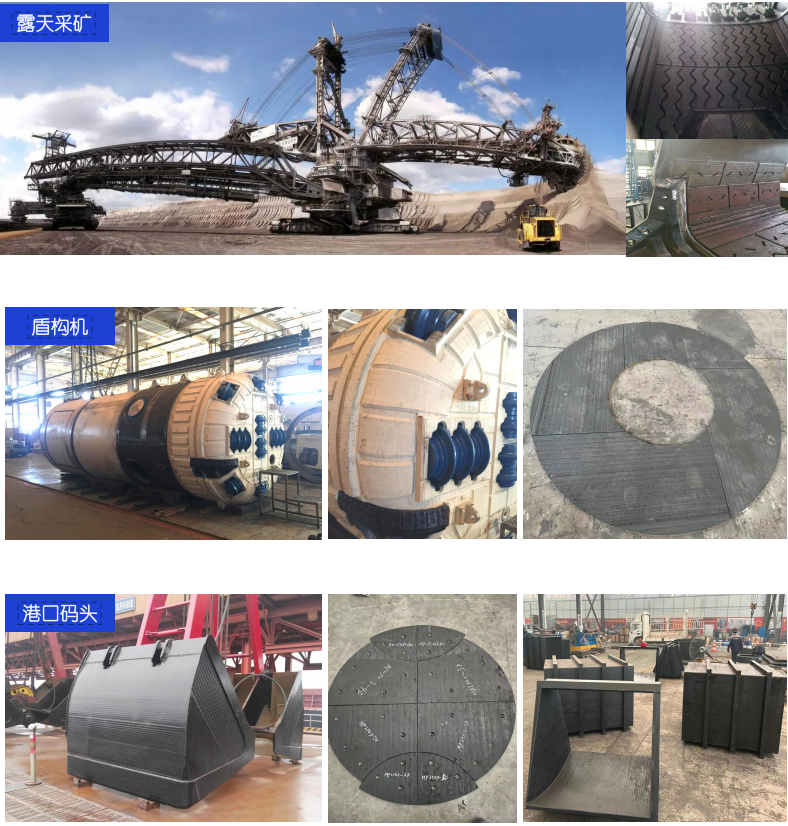

1. Mining/Building Materials Industry (High Impact + Severe Wear)

Crushing Equipment: Welded wear-resistant liners, jaw plates, cone crusher walls, and impact plates for crushers (to combat impact and abrasive wear during ore crushing);

Conveying Equipment: Rubber lagging for conveyor belt pulleys and hopper/chute liners (to mitigate impact and sliding wear caused by falling materials);

Grinding Equipment: Welded wear-resistant liners for ball mills and coal mills (to mitigate abrasive wear caused by steel balls and materials).

2. Construction Machinery Industry (Mobile Wear + Impact)

Excavators: Excavator bucket teeth, bucket floors, and ripper tooth tips (intensive wear from contact with gravel/rock and impact from excavation);

Shovel-moving equipment: Loader buckets, bulldozer blades, and motor grader blades (sliding wear from earthmoving/mining operations);

Compactors: Roller wheel rims (friction wear from road/site compaction)

3. Power/Energy Industry (Wear Resistance + Heat/Corrosion Resistance)

Thermal/Biomass Power Generation: Coal Mill Wear Plates, Coal Feeder Chutes, and Coal Drop Pipes (Coal/Biomass Pellets are subject to wear; some cladding linings must withstand temperatures of 300-500°C);

New Energy (Wind/Hydropower): Wind Turbine Gearboxes and Hydropower Gate Guide Rails (Low wear and high reliability requirements require cladding wear plate layers to enhance surface hardness);

4. Metallurgy/Chemical Industry (Wear Resistance + Corrosion Resistance / High Temperature)

Metallurgy: Blast furnace bells/hoppers, converter oxygen lance nozzles, continuous casting rollers (high temperature resistance + corrosion wear from molten steel/slag);

Chemical Industry: Acid/alkali material conveying pipelines, reactor linings, and agitator impellers (wear-resistant layer must be compatible with acid and alkali corrosion, such as nickel-based alloy overlay);

Non-ferrous Metals: Copper/aluminum ore flotation machine impellers and conveyor chutes (slurry erosion wear + mild corrosion)

5. Transportation/Port Industry (Heavy-Load Wear)

Ports and terminals: Ship unloader hoppers and stacker/reclaimer boom liners (to protect against impact wear from ore/coal loading and unloading);

Mining transportation: Wear-resistant plates for mining truck bed panels and dump truck buckets (to protect against sliding wear from heavy-loaded materials and reduce deformation);

Transport feroviar: Șine de macaz și benzi de rulare (pentru a proteja împotriva uzurii prin frecare pe termen lung și a prelungi durata de viață prin repararea sudurilor).

6. Industria generală de mașini (armare locală la uzură)

Pompe și valve: Corpuri/rotoare pompe pentru nămol, suprafețe de etanșare ale valvelor de oprire (eroziunea fluidelor + uzura particulelor solide);

Mașini-unelte: Ghidaje pentru mașini-unelte, muchii de așchiere (Uzură locală de la tăierea/ștanțarea metalului; reparare cu plăci de uzură de placare în loc de înlocuire completă)

Oriunde există o tendință de uzură și unde este necesară durabilitatea pe termen lung, este potrivit să se utilizeze plăci rezistente la uzură pentru placare - acest lucru nu numai că reduce costul total al echipamentului (nu este nevoie să se utilizeze oțel rezistent la uzură scump pe toată suprafața), dar crește și durata de viață a pieselor cheie.